We would like to share with you the work we have just finished for our customer – a processed vegetable producer.

The client had an architectural and production plan. As a result of consultations, we managed to find the optimum room heights, optimize their insulation and collect information that would allow us to design an installation that was optimally matched to his needs.

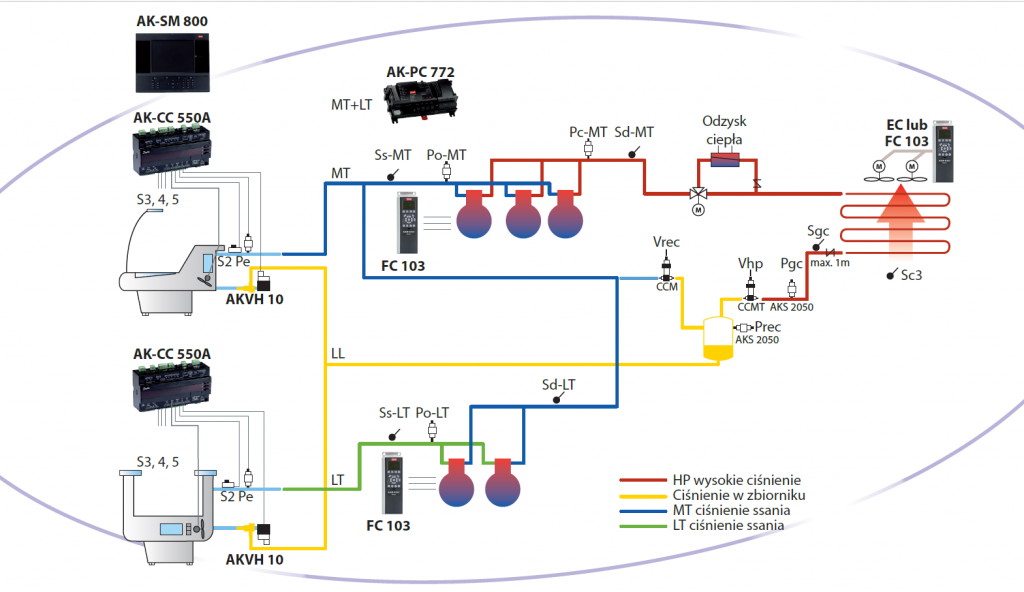

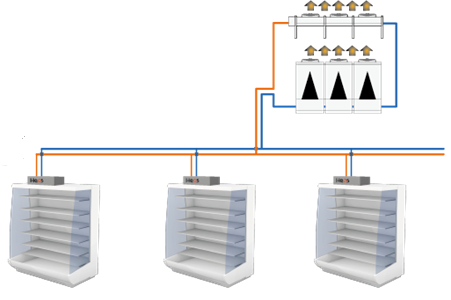

21 rooms with a total area of 3200m2 which consist of storage rooms, corridors and production areas are cooled by 4 compressor units with a total power of 550 kW. We have foreseen a heat recuperation system for heating water for a bioreactor (10m3/week at +38°C), hot domestic water and heating of the freezer floor.

Clients production technology includes pasteurisation which requires heat and cooling simultaneously. For this purpose, we designed a dual-function cooling / heat pump with 100 kW cooling capacity and 100 kW of heating power. Due to the required hot side temperature, we have proposed R744 (CO2) as a cooling agent. In this way we eliminated the need for a gas furnace and increased the efficiency of the refrigeration plant – significantly reducing the operating and production costs.